Wet-to-dry expansion: Part 3

Great to have the next (and third) major instalment of research linked to my RAEng Research Fellowship out there. And enormous kudos to Pawel, for whom this paper is the first journal paper from his PhD research! Certainly one to be proud of.

You can download the open-access article for free here.

The paper is one of the first to explore the wet-to-dry expansion of organic fluids in converging-diverging nozzles using non-equilibrium computational-fluid dynamic simulations. The work extends my previous which was looked at the wet-to-dry cycle from the perspective of cycle and turbine design and the development of a nozzle design tool.

Find out more about the previous work here:

- Paper on cycle and turbine design for wet-to-dry cycles

- Paper on a nozzle design tool for wet-to-dry cycles

Non-equilibrium CFD simulation of the wet-to-dry expansion of the siloxane MM in a converging-diverging nozzle

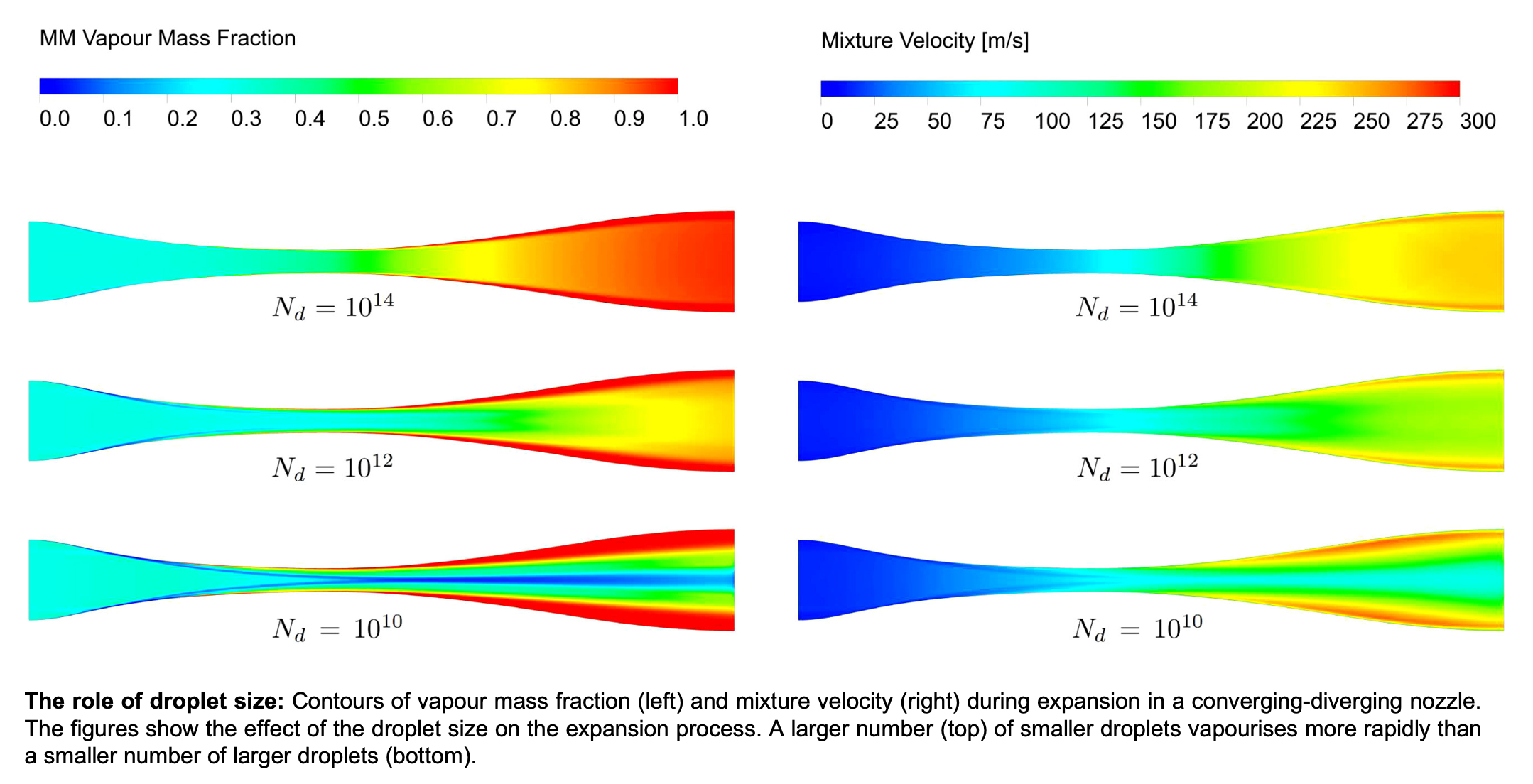

Wet-to-dry organic Rankine cycles could generate 30% higher power outputs in the temperature range of 150 to 250 °C compared to existing single-phase cycles. Since the expansion is only partially wet, turboexpanders could potentially be applied provided that the wet portion of the expansion is confined to the stator to avoid erosion in the rotor. To assess the feasibility of achieving complete evaporation in the stator, two-dimensional non-equilibrium numerical simulations of the wet-to-dry expansion of siloxane MM in a coverging-diverging nozzle are performed for the first time. The simulation setup is first validated against published experimental data, and a sensitivity study is conducted concerning the selected interphase models. The model is then applied to simulate expansions from inlet pressures ranging from 478 to 1250 kPa and vapour qualities from 0.1 to 0.5. Moreover, the droplet number density was varied between 1010 and 1014. The results show that the evaporation rate, the extent of non-equilibrium effects and the flow’s spatial uniformity are predominantly dependent on the droplet size. Expansions beginning with droplets smaller than 20 μm resulted in complete mixture evaporation and negligible non-equilibrium effects in almost all investigated cases. For larger droplets, ranging from 40 to 100 μm, full evaporation could only be achieved for inlet pressures above 750 kPa and inlet qualities above 0.3, whereas for lower pressures, the outlet vapour quality varied between 80 and 90%. For droplets larger than 200 μm, there is a significant delay in evaporation resulting in outlet quality typically between 40 and 70%. Larger droplet flows are characterised by substantial velocity slip, temperature difference, phase separation and lateral velocity variations. Having said this, droplet breakup analysis indicates that droplets larger than 100 μm are likely to undergo breakup, which could enhance the evaporation rate; however, this requires further investigation. In conclusion, high inlet pressures and high inlet qualities are preferred from the perspective of ensuring dry-vapour conditions at the nozzle outlet.

Acknowledgement

This project was supported by the Royal Academy of Engineering under the Research Fellowship scheme (2019–2024).