First milestone of my RAEng Research Fellowship and my latest publication

Last month, I hit one of the first major milestones of my Royal Academy of Engineering Research Fellowship, which resulted in the first key publication of my fellowship research. Honestly, it has felt a relatively long time coming, but I can safely say that it is one of the pieces of research that I am most proud of. So, what is it all about?

If you have already explored other parts of my site, you may already be aware that a lot of my research deals with the topic of waste-heat recovery, and my fellowship is exploring a next-generation waste-heat recovery technologies based on two-phase expansion.

But if not, let’s cover the basics.

Well, currently waste heat from a range of industries is currently rejected to the environment. Thus, the recovery of this wasted energy could have a significant role in reducing the environmental footprint of the manufacturing sector and help to ensure future manufacturing practices are sustainable. One of the most promising groups of waste-heat recovery technologies are those that are able to convert this waste heat into electricity, which includes the organic Rankine cycle (ORC). However, current ORC technologies typically have relatively poor thermodynamic performance and are associated with high costs.

In these existing ORC systems, power is produced by the turbine which is designed to operate completely with a fluid that is in a gaseous state. This is done to avoid the presence of liquid droplets within the turbine that could damage or erode the machine. However, previous investigations have suggested that the admission of a two-phase fluid, which is a combination of liquid and vapour, could enhance the power output from these systems. Thus, if a suitable turbine design intended for two-phase operation can be designed, the performance of ORC systems could be enhanced.

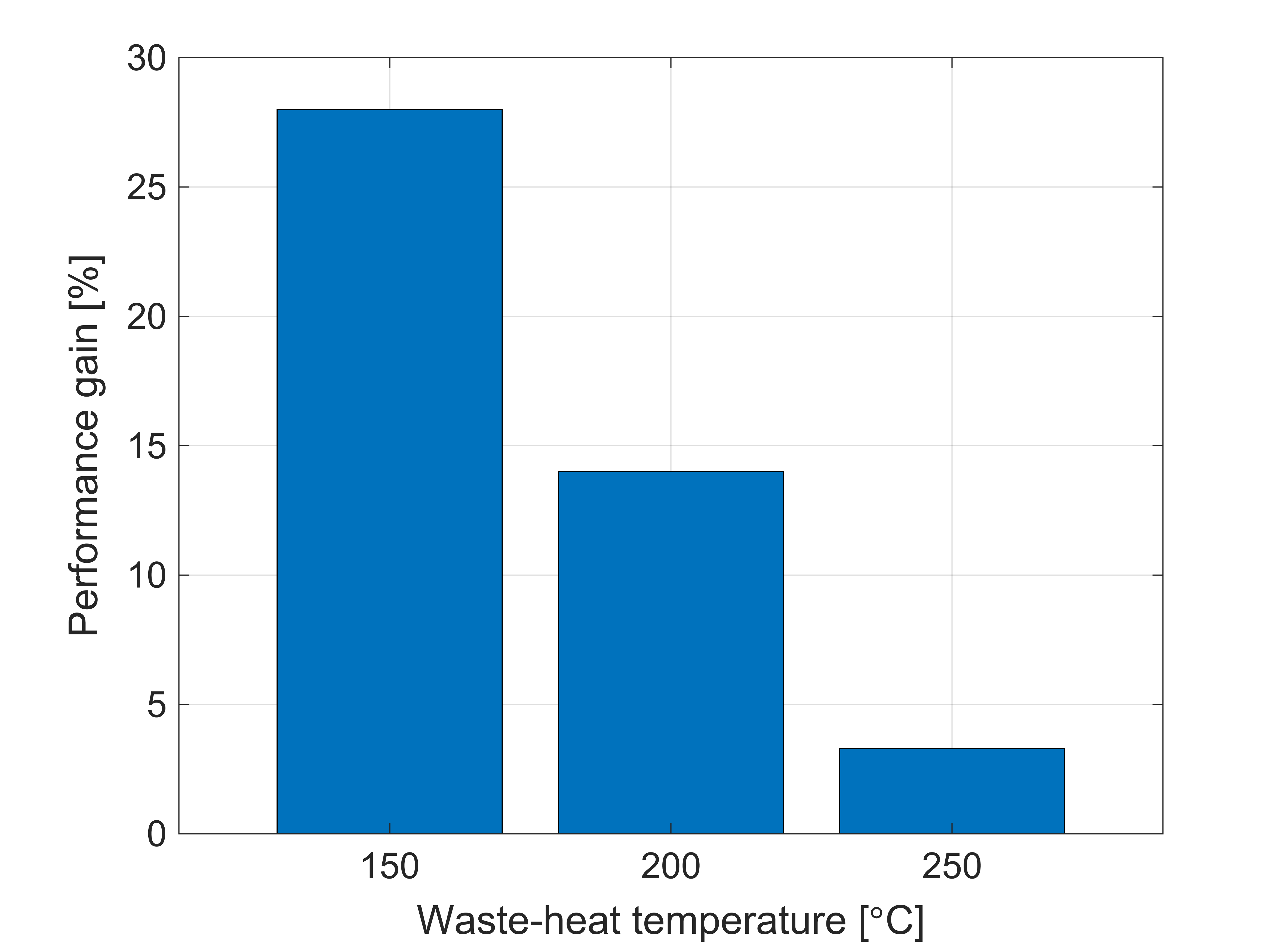

The first phase of my fellowship has investigated a novel organic Rankine cycle system, based on two-phase expansion, and the latest paper has established the potential thermodynamic improvements through a series of numerical simulations of the system. Specifically, modern fluids whose properties could help to mitigate concerns around turbine damage have been considered, which in turn could allow the benefits of two-phase expansion to be realised. The results have indicated that for waste-heat temperatures up to 250 degrees Celsius, the introduction of two-phase expansion could generate up to 28% more power than conventional single-phase systems.

In addition to that, a preliminary turbine design study has indicated feasible turbine geometries can be obtained. The next steps will involve more in-depth design and analysis of the turbine to confirm if this is the case.

Paper details

Cycle and turbine optimisation for an ORC operating with two-phase expansion

You can check out the full paper here.

Abstract

Previous investigations suggest the power output from waste-heat recovery organic Rankine cycle (ORC) systems could be enhanced by up to 30% by operating with two-phase expansion, which could reduce cost and aid in the more widespread deployment of ORC technology. However, there are limited expander technologies suitable for such operation. The aim of this research is to investigate a novel ORC system that operates with wet-to-dry expansion permitting the use of a radial-inflow turbine. Specifically, through the exploitation of molecularly complex fluids the wet-to-dry expansion could be achieved across a single turbine stage, whilst the two-phase region is confined to the stator vane. Thermodynamic system optimisation is completed for potential fluids in which the degree of reaction is used to differentiate between the stator and rotor expansion processes. The results reveal that siloxanes are optimal fluids, and that for heat-source temperatures of 150, 200 and 250 degrees Celsius the two-phase systems could generate up to 28%, 14% and 3% more power than single-phase systems, respectively. Following this, existing mean-line turbine methods are extended to two-phase turbines under the assumption of a two-phase homogeneous fluid under thermal equilibrium, which is supported with numerical simulations of a two-phase stator vane. The mean-line turbine optimisation for the 200 degrees Celsius heat source is then conducted, with the optimal system corresponding to a turbine inlet vapour quality of 0.1 and degree of reaction of 0.4, with lower reaction leading to lower turbine efficiencies. More generally, feasible rotor geometries can be obtained, and conditions with the rotor are expected to remain subsonic. Whilst stator outlet Mach numbers range between 1.5 and 2.1, and stator throat widths below 1 mm are required, the CFD simulations indicate that wet-to-dry expansion can be successfully realised within the stator. In summary, these results provide the first positive demonstration that a 30% improvement in power output could be achieved with a two-phase ORC system operating with molecularly complex working fluids and a radial-inflow turbine.

Acknowledgement

This project was supported by the Royal Academy of Engineering under the Research Fellowship scheme (2019–2024).